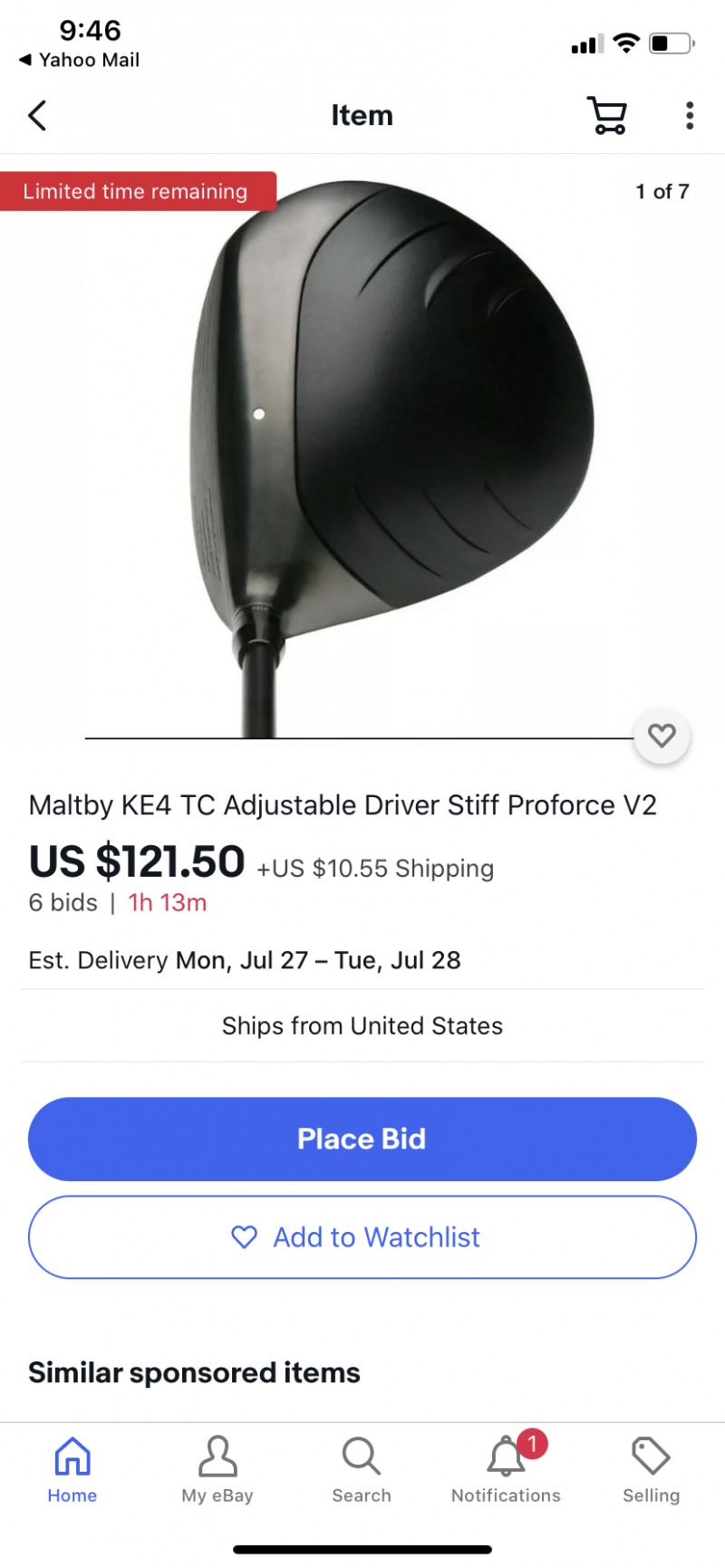

Maltby KE4 Tour TC driver....

KCee if you need my address email me at nrobin321@gmail.com

a month later

a year later

Ordered a new head for a guy I work with. I’m wondering if they’ve had issues with shafts not bonding to the adapter? Check out the inside of the adapter

- Edited

The last Maltby driver I really really really liked was the original CT250.

colej the 2 smooth adapters didn’t rough up easily. I had to use a random piece that I found in a Dremel box to really rough it up. I’m not a huge fan of the collared ferrules. To me I would rather have that area for an additional epoxy bond. I usually use some shafting beads so centering the shaft is rarely an issue.