First 9 with the Swing Science FC-One Plus driver in bag yielded some of the best driving in years. I match up well with the loft with a medium-high tee height and the shaft Swing Science FC-One Plus "A" 65g shaft. The shaft weight is in my go zone. Ultra light shafts in drivers don't give me more distance they lead to hook-push. The slight +.05 face angle is just enough for me personally much less than what one sees on most drivers these days of draw biased or +.1 and more closed face angles. The MoI heft match is about right along with playing length. Straight to slight draw in general no push-slice.

What did you build today?

- Edited

Going hunting for birdies, built me some Heaters.

- Edited

scotts33 Ultra light shafts in drivers don't give me more distance they lead to hook-push.

Imagine the troubles you'd have with my drivers.

46-46.5"

A flex shaft weights of 52-55

Head weights of 204-206g.

If anything goes right(rare) or even left, that is not my club. That was me.

Swing Science has always had good driver heads. Hybrids were nice also.

Things are getting heated in the garage. 1/3 done, although it could use some touchups.... And I might add classic style face punching/drilling next to the grooves if I'm feeling confident. Made from a TourSpec forging.

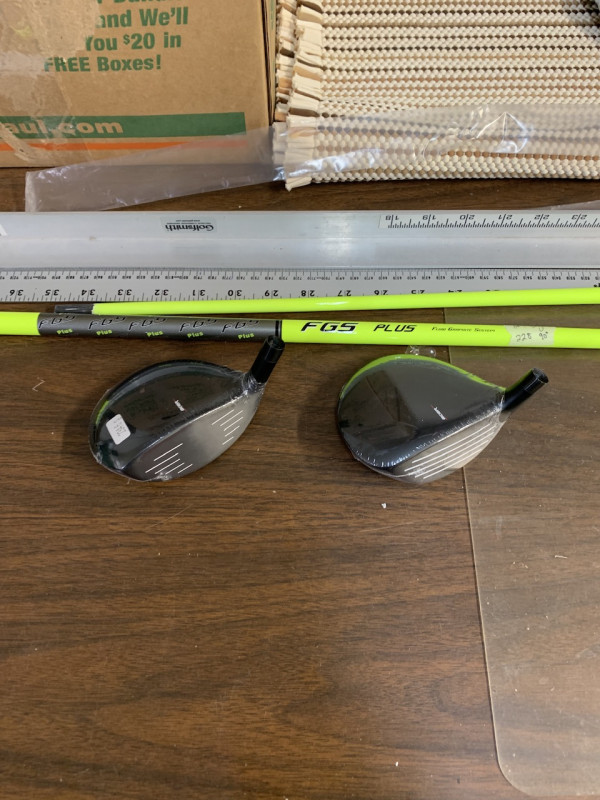

Acer 7 and 9 woods.

I put a Taylormade Tip on my HOF Express shaft. One of my favorite shafts. Had a tip on there before but the epoxy was bad. The ones I hit, before it twisted, were nice. Look for wars to hitting it.

I’m THIS close to taking the tip off my Paderson. It’s a love/hate relationship with that shaft. Unfortunately that relationship pops up during the round. Soft tip and soft handle are not a great mix for me consistency-wise.

Got my money's worth out the new grinder attachment now I think.

My approach started with measuring the COG on the face and marking it, as well as using a black sharpie to trace out the sole grind, face shape and other details I wanted. Then the grinding steps were:

- Sole first, for me this involved also getting the flat profile for the bottom of the face ground in as well

- Edges of head to get desired shape

- Hosel, done while turning the whole head. At this point have to measure the weight of the head to see how much work is left. Usually at this point I had 10g left to go.

- Rest of design as marked out - I got creative and used the edge of the belt & wheel to get the details on the back cut in.

Grinding was done with 60 grit first, then red (course) surface condition belt, followed by blue (fine) surface belt. All of this was done on a 2" by 48" belt grinder attachment bolted to an older 3/4HP grinder. If I had to do it again I'd use 120 grit after the 60 grit before going to the belts, as some deeper scratches weren't totally eliminated by the belts.

Face dots were done using a straight edge and a utility knife to add a faint line where I wanted them, then center punched and drilled by hand.

ode Reverse taper are hard to find.

A little late to the party… https://feelgrips.com/en-ca

For the Mrs.

PING G425 MAX with a Graman UL440 Limey in Senior Flex...She Loves It!!!