All parts are test printed now. The 1st picture shows how the cradle that holds the tachometer will look. The knob adjusts the height of the laser beam. It seems a bit unstable so I might add a second adjusting knob at the other side for stability.

On the other end of the setup is the clamp. Springs and toggle clamps are in the mail from China, but I already was able to test it using clamp spreaders to clamp it on the workbench. I opted for the 1" clearance above the board and the shaft vibrates well.

Basically there's two different kinds of frequency machines on the market : with an optical switch (infrared or laser) and with a pressure switch build into the clamp. They work slightly different.

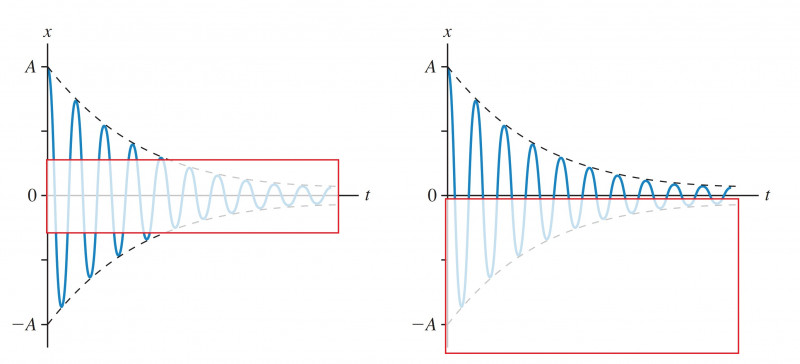

The optical switch blocks the light when the shaft travels through the light beam and such triggers twice per cycle (once the way up and once the way down - left graph), as such when the amplitude of the vibration falls below the thickness of the shaft it no longer triggers. The decline of amplitude is exponential so one needs a rather large starting amplitude to have sufficient cycles to make a measurement.

Pressure switches trigger only once per cycle from positive to negative pressure (relative to the pressure at rest - right graph), so they will continue to trigger with much smaller amplitudes. The build is much more complex however.

The tachometer reflects light from the shaft as opposite to blocking it off, so the working is similar to an optical switch with source and receiver at opposite sides of the shaft. It just inverts 0's and 1's. I intend to attach a little reflective flag to the shaft with small 3D-printed clips, and aim the laser not to centre of the shaft but just at the edge of triggering. The flag will reflect as such half a cycle all the way to the bottom, and will as such trigger only once a cycle and will also trigger with small amplitudes just as a pressure switch does. And with only one trigger per cycle the reading on tachometer will not have to be divided by 2.

Here's video of a frequency machine that seems to use a laser and reflective tape to produce two triggers per cycle:

So in theory it should work, we'll see how it performs in real life. I'm measuring much closer to the butt end so the amplitude is much less then in the video. I've tested this principle with a handheld laser and a piece of masking tape as a flag, observing the dot projected on the wall behind the setup; the dot kept on flickering uptill rather small amplitudes at a rate of 4-5 cycles/sec (eyeballing it), so it looks promising,